Aluminum Extrusion for LED Linear Lighting

As the adoption of light-emitting diodes (LEDs) was revolutionizing the lighting industry, the design and composition of commercial and architectural light fixtures were also undergoing significant improvements. This evolution of luminaire design has featured aluminum as a preferred material, and extruded aluminum as the premier construction process.

What is extruded aluminum?

The process of extruding a metal was first used in the 1790s for manufacturing lead pipes. Over the next century, the process was also applied to additional materials like copper and brass. Aluminum was discovered in the early 1800s but the ability to extrude the new metal was not developed until approximately 1900. Given the relatively light weight and strength of the material it became a popular manufacturing choice with automotive and military industries, among others.

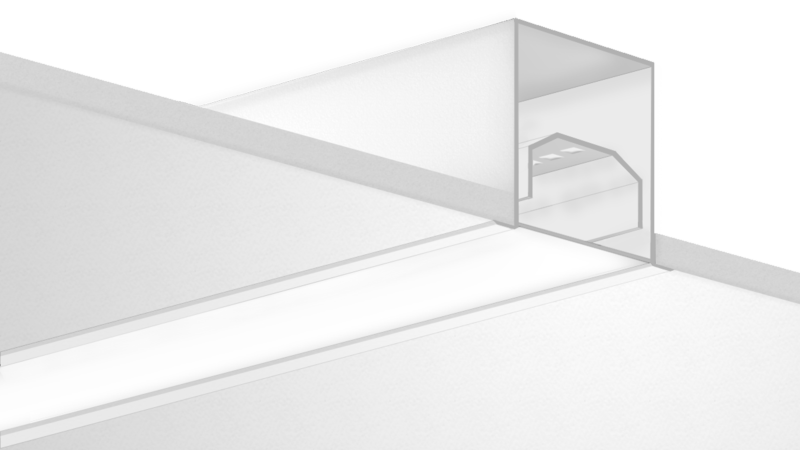

Extruded aluminum is now ubiquitous with modern life. One of the reasons for the popularity is the efficient and economical process and limitless creativity that can be applied to extruding aluminum shapes. Using dies specifically designed to create the desired shape, aluminum alloy is pressed through the die and extruded into the required form. These extrusions can be run in long lengths, and the resulting structure is not only aesthetically pleasing with an attractive surface finish, but also very strong in relation to the weight.

Advantages for linear lighting construction.

As mentioned, the surface finish of extruded aluminum provides an excellent surface for elegant or modern sleek light fixtures. However, the real advantage that extruded aluminum has over materials like stainless-steel is its strength and ability to retain its shape over long runs.

Less desirable construction material can cause rows of suspended linear lights to take on a wavy appearance as they become misshapen over time. The strength of the extruded aluminum also serves to keep lenses in place and provide a more reliable alignment point for multiple continuous fixtures. Extruded aluminum is also an excellent thermal conductor that assists in the dispersion of heat to protect the LED components.

Aluminum extrusions are also excellent reflectors of light and deliver a corrosion-resistant material for any environment or application. Combine these properties with the non-degradation of the material and its ability to repeatedly recycled, extruded aluminum light fixtures are also an environmentally-friendly choice.

The right choice for professional lighting needs.

American Linear Lighting’s extruded aluminum linear fixtures are an ideal choice for your business, retail, educational, healthcare, or other professional environments. Whether it’s a suspended design, wall-wash application, or part of a grid system, the various direct and indirect luminaire options are designed for easy installation and a full library of BIM models.